How did instrument clusters evolve ?

Over our almost five decade journey, we have had a front row seat to the evolution of dashboard instruments, in trucks / buses / tractors / construction equipment and industrial markets. The pace of change was very slow to begin with, but has really become much faster in recent years. The drivers have been regulations and also general spread of technology into every day life which has created a demand for more and more features.

When our company began in 1976, there were very few clusters in our markets. Round gauges dominated. And among them, mechanical gauges occupied a position of pride. Good accuracy, robustness and no need for external power. The aesthetics were very pleasant too. However, they were not easy to make, and our highly skilled operators helped us dominate that market. Nor were they cheap, since apart from high labour content, many of them used expensive materials, which led to the heavy duty construction. They needed a lot of effort to fit at customer end too, since each gauge had to be mounted individually.

The first transition was to electrical gauges ( still round), driven by inputs from sensors, which gradually led to electronic round gauges too. the complexity of fitting these at customer end went up, since now electrical connections had to be made individually too.

However, the round gauges were very serviceable, and required low NRE charges to customise, so they were well suited to the production volumes of the times.

The first instrument cluster was simply a sheet metal panel, with round gauges mounted on it, and a small wire harness to make the connections. the customer could instal it just by plugging in a matching connector and tightening four screws.

However, the high number of connections ( mechanical and electrical), most of which were manually done, led to chances of errors in the manufacturing process. And also were the weakest points in the system as far as reliability was concerned.

So, this led to a more integrated ( but still with an analog front end) cluster, with very few manual connections, and much better aesthetics.

What is a modern analog instrument cluster and what are its advantages ?

A modern analog instrument cluster comprises pointer driven gauges, hard wired tell tales symbols and an LCD display which can have an odometer, trip odometer , clock etc. So technically, the cluster displays both analog and digital display, but since pointers occupy the largest chunk of the real estate, we still call it an analog cluster. Over time, the front end stayed analog, with moving pointers, but the back end kept getting more and more high tech. small LCD displays replaced the figure wheels in the odometer, PCBs replaced the wire harness and stepper motors replaced the air core movement. The number of tell tales grew with increasing regulations, and lighting soon became LED driven. Leading to a highly reliable, very nice looking product, which a driver could read pictorially at a glance. In other words, the driver just had to take a quick look, and if all the pointers were close to the centre ( and no tell tales flashing), he knew there was nothing wrong.

The back end of the cluster is partly digital in some cases too, taking inputs from a J1939 protocol data bus, but when we say analog cluster, we refer to the front end.

Things were going well for the analog instrument cluster, and they were leading to a smooth driving experience. They enjoyed the following advantages:

- Simplicity: Analog clusters are easy to understand, as they have been used for decades and also have a pictorial view

- Low cost: They are cheaper to maintain and produce.

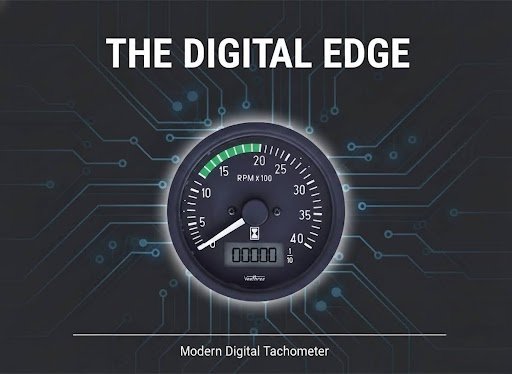

What is a Digital Instrument Cluster and how did they become popular ?

Digital instrument clusters replace the pointers, LCD and the tell tales with a single LCD or TFT display.

The inputs to the cluster are usually a mixture of analog and digital inputs, but as long as the display is digital, the cluster is considered digital.

TFT clusters embody the spirit of digital clusters and all they can do, so going forward we will treat TFT clusters as digital clusters.

So, analog clusters were dominating the market, but as vehicles became more complex, software driven and connected; the users need for information, more features and personalisation grew. Analog clusters could display fixed parameters, and it was expensive to customise the front face even for bulk production, plus personalisation was not possible. The rise of smartphones ensured that users were now comfortable with the digital display.

What are the advantages of digital clusters

These systems use software-driven interfaces that can integrate speed, navigation, infotainment, ADAS (Advanced Driver Assistance Systems), and even smartphone connectivity, all in one customizable screen.

Advantages of digital clusters:

- More Functionality : digital clusters can connect with phones to offer navigation, with cameras to show videos, apart from the regular functionality of engine based parameters

- Better accuracy and reliability : Since there are no moving parts in the digital cluster, accuracy is higher. There are no parallax errors in digital displays too. Reliability much higher too, since there is no wear and tear due to moving parts.

- Better visualisation & more information : The screen is programmable, so it offers possibilities of pop – ups, etc. making important information more visible. The TFT screen can be scrolled to offer many screens by swiping / buttons, showing a wealth of information. All this information can be displayed without cluttering the dashboard.

- Easy Driver level Customization: Drivers can choose between display modes, layouts, and color schemes

- Integration with other devices: Digital clusters can work seamlessly with infotainment, navigation, and connected vehicle systems.

- Modern aesthetics: Sleek, futuristic visuals align with today’s design standards for electric and premium vehicles.

- Cost saving opportunities: The electronics used in the cluster is more powerful, since it needs to drive the TFT. While on a standalone basis, this can be more expensive, but this more powerful electronics may be used to combine features of other vehicle electronics , and leading to cost saving opportunities

- Higher sales / margins for OEM : A TFT display creates a more high technology look for the entire vehicle; plus it offers a high number of extra features. This can lead to higher sales or higher margins or both for the OEM.

- Less expensive factory level customisation: New variants can be without any changes in the electronic hardware, merely by changing the software.

Limitations:

Digital clusters can be more expensive to develop and may require higher processing power. Prices of TFTs are still high though they are coming down. And sometimes, people prefer an analog cluster for the aesthetics, similar to the trend in the wristwatch industry.

How Indication Instruments is Powering the Transition

At Indication Instruments Ltd, we are proud to be part of this evolution from analog to digital. With decades of experience in designing reliable analog gauges, we’ve leveraged that expertise to develop advanced digital and hybrid clusters that combine tradition with technology.

Here’s how we’re making it happen:

a. Hybrid Instrument Clusters

Understanding that not every market or vehicle segment is ready for a full digital shift, Indication has developed hybrid clusters, combining traditional analog dials with digital displays. This offers the best of both worlds: familiarity with modern functionality.

b. Customizable Digital Displays

Our digital clusters feature fully customizable interfaces, allowing OEMs to tailor layouts, themes, and data visuals. From high-end luxury dashboards to rugged commercial vehicles, we design solutions that reflect each brand’s identity while enhancing user experience.

c. Precision Engineering and Testing

All Indication clusters undergo rigorous validation, calibration, and reliability testing to meet international automotive standards. Our facilities are equipped with AI-driven test benches and simulation tools that ensure consistency, accuracy, and durability.

d. Scalable Technology for OEMs

We offer scalable platforms from entry-level displays to advanced clusters, ensuring flexibility for automotive manufacturers. Our modular architecture allows for easy integration with telematics, CAN systems, and AI-based driver information systems.

FAQs

1. Is the future of clusters fully digital ?

As vehicles become increasingly connected and autonomous, digital clusters will continue to edge past analog clusters. With new changes in technology, we can see digital clusters evolving into more advanced versions such as HUD displays which project on the windscreen. Some people feel that when vehicles turn fully autonomous, there wont even be the need for a display, but that doesn’t seem too likely. We can also expect some sort of a comeback from the analog cluster too, if the watch industry is any indication.