In most factory environments, product quality tends to be a department-level concern, typically that of QA or QC. But anyone who’s put in enough time on the shop floor knows the truth: quality is a result of the system, not a feature of a department. And that’s where the Shingo Model deviates. Instead of encouraging more inspection or stricter controls, the Shingo approach focuses on culture, behaviours and principles that guide toward reliable quality at the source.

In the last few years, especially as companies compete on speed, user experience, and reliability— Shingo techniques have become more timely than ever. They provide a disciplined but human-focused approach to scale quality without process overengineering. Here’s how they impact.

1. Quality starts with culture

One of the biggest epiphanies from the Shingo Model is that quality is not something technical systems can deliver. You can bring in poka-yoke, standard work, 5S or automation, but if they don’t believe in quality, they take no pride in keeping defects at bay, the gains remain superficial.

Shingo emphasizes Respect for Every Individual and Leading by Humility as core principles. The attention therefore moves away from finger pointing at operators to instead recruiting them. Where frontline teams feel appreciated, they give a damn about getting it right the first time.

For example, a team assembling automotive instrument clusters or calibrating pressure gauges often detects issues early when team culture encourages ownership. This one change by itself brings ownership and slashes rework.

2. It drives “quality at the source” rather than end-of-line policing

For many factories, end-of-line inspection is still heavily relied upon. It’s costly, inefficient and does not prevent defects – it only detects them.

Shingo methods emphasize quality at the source, that is,

- Operators identify and fix issues on the fly.

- Each step contains its own error checking.

- Line teams halt production when anomalies arise.

That means instant correction, rather than batch-wise emergency alarm fighting. Over time, this discipline cuts down the need for inspection because the processes become intrinsically more reliable.

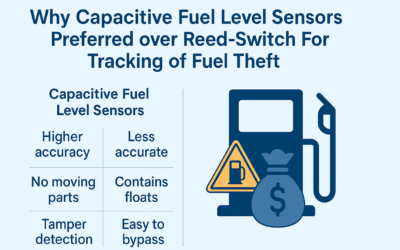

This approach is crucial in production lines manufacturing fuel level sensors, DEF sensors, analog gauges, electronic speedometers, RPM tachometers, or dashboard instrument clusters, where any defect can disrupt vehicle safety and customer trust.

3. Shingo principles backing continuous improvement that endures

Why most quality initiatives fail — because they fade. They begin with a fanfare, but after months, banners blur, audits are mundane, and the good old ways creep back in.

Shingo addresses this by encouraging three levels of improvement:

- Cultural enablers

- Continuous improvement

- Enterprise alignment

Continuous improvement tools like Kaizen and value stream maps and PDCA and standard work provide structure, but it’s the cultural piece that sustains them. Shingo instructs that habits are powered by beliefs — and lasting change occurs when habits match those beliefs.

This is to say quality improvements no longer rely upon a handful of passionate and energetic leaders, it becomes institutionalized.

4. Shingo and Quality in Automotive Instrumentation

In industries such as automotive gauges, fuel level sensors, pressure gauges, instrument clusters, and digital speedometer clusters, Shingo principles become even more critical. Products like pressure sensors, coolant temperature sensors, electronic tachometers, fuel indicators, and dashboard instrument clusters require consistent manufacturing discipline because even a minor variation can affect vehicle performance. By promoting stable processes and quality at the source, the Shingo Model ensures reliability across components such as fuel level sensors, speed sensors, engine temperature gauges, and modern digital instrument clusters used in trucks, buses and EVs.4. It generates deterministic and reliable workflows

In the end, good quality comes from stable processes. Shingo assists organizations in discovering the underlying instability causes – such as:

- Variation in work methods

- Poorly maintained equipment

- Lack of clear standards

- Frequent changeovers

- Overburdened operators

Applying Shingo principles gives teams the tools to organically shift towards

- Clear standard work

- Visual controls

- Mistake-proofing

- Flow and pull systems

- Preventive maintenance

Once processes are humming, defects fall almost of their own accord.

5. Respect-Based Problem Resolution Improves Products

One of the Shingo philosophy’s strongest pillars is that the doers know the work best. This is devastatingly powerful for quality improvement.

Rather than having the managers or engineers remotely attempt to infer the root cause, the operators are engaged in

- Problem definition

- Suggesting countermeasures

- Testing solutions

- Standardizing improvements

This ‘bottom-up wisdom’ results in more workable solutions and greater buy-in. They’re fixed for good — not patched for now.

6. It maps excellence to company mission

Most quality defects occur because teams are pursuing local KPIs – output, cost, or speed – instead of doing things right.

Shingo emphasizes alignment by ensuring that every employee knows the mission: to generate value for the customer. When purpose is the anchor, decisions organically weigh quality, cost and delivery in equilibrium rather than trading one off against the other.

A line leader could say,

We could run the line harder, but if quality will suffer, we’ll clear the bottleneck first.”

This mindset shift safeguards long-term brand equity.

7. Shingo motivates going to the Gemba

Good issues rarely get resolved in board rooms. Shingo encourages leaders to conduct Gemba walks — to observe processes firsthand and to mingle respectfully with workers. When leaders are visible, accessible, and inquisitive — not critical — quality impediments rise to the surface rapidly.

You start hearing things like:

The fixture’s a little loose, so sometimes alignment gets off,

or

We bypass this during rush hour because the tool clogs.

These insights barely land on any quality report but are crucial in preventing defects.

Final Thoughts

Quality improvement isn’t about recruiting ever more inspectors, or honing the specification, or stacking on audits. The Shingo methods make us remember that quality is people, process and purpose aligned. By instilling a culture of respect for people, promoting kaizen, and orienting everyone towards the customer, Shingo gives the organization a powerful sustainable process for delivering world-class quality. Whether you manage a single line or a whole plant, Shingo principles can transform quality from a struggle into an organic side effect of how people work every day.