Introduction to temperature gauges

The temperature gauge is one of the most important gauges to denote the condition of internal combustion.

The history of the temperature gauge

The humble mechanical temperature gauge, which did its job over several decades, lost its prime position to the electrical air core gauge, which was used in combination with a temperature sensor. There have been many technology upgrades since then, and the air core itself was replaced by the stepper motor inside the gauge. The stepper motor was controlled by a microcontroller, so it became possible to manipulate the pointer movement in a far more sophisticated manner. You could increase or decrease damping, make the scale non linear, create a dead zone too, to avoid alarming the driver. It was a matter of time before digital technology stepped in, and the input to the temperature gauge was digital, the most common being J1939 protocol based inputs. And finally you also had a bar graph or even virtual.

It seemed the mechanical temperature would die a natural death, since it was a low technology product. It was difficult to install, readings could be affected by ambient temperature, required a lot of skill to manufacture ( and those skills were not easily available any longer), failure levels were higher than solid state products, etc.

However, it is still very around, albeit as a niche product. In certain applications it is still the most suitable product and simply has no substitute.

How does a mechanical temperature gauge differ from a home thermometer ?

Before we go there, there is a little bit about the design and principle of operation of mechanical temperature gauges. Basically the mechanical temperature gauge is similar in principle to the mercury thermometer we used ( or still use) to measure our body temperature or fever ! the main differences are:

- There is a dial instead of a calibrated glass tube as the readout

- The temperature range is generally 40-120C instead of 95-110F ; and as a result, does not use mercury as a medium

- it is significantly longer and allows the dial to be mounted in front of the driver even though the engine / radiator is far

- it is far more robust

What are the construction details of a mechanical temperature gauge ?

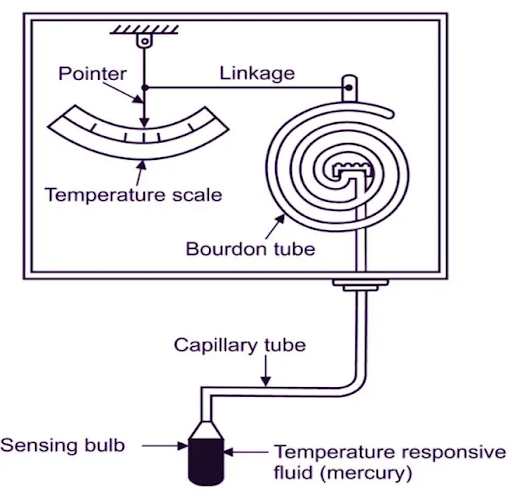

Mechanical temperature gauges basically consist of a sealed capillary containing a medium inside, on one side of which there is a sensing bulb and on the other side is the coiled bourdon tube.

The bulb is inserted into the radiator (or other suitable receptacle) from where it senses the temperature to be measured. The volume of the bulb is kept high, so that when it expands ( as the temperature increases), it creates an internal pressure in the capillary which leads to the bourdon spring opening out and moving the pointer.

Two types of used mediums are commonly used, Either and xylene . IIL is perhaps the only company in the world making xylene based mechanical temperature gauges.

- xylene has a boiling point of 140 °C ; so it stays in the liquid form over its working range and hence lends itself very nicely to a linear scale dial. In fact sometimes it is even used for +200°C gauges, and due to the xylene being pressurised, it stays in the liquid stage until then too.

- Ether has a boiling point of about 34°C, so it stays in a vapour state for most of its range. Its expansion is exponential as the temperature rises, so the dials of an ether filled gauges are nonlinear.

Why is the mechanical temperature gauge still being used?

No Power Supply needed

Mechanical temperature gauges are completely self-operating devices. Because of this advantage, industries prefer mechanical temperature gauges over digital alternatives, especially for critical safety monitoring. For example, in a diesel engine cooling system or a boiler, a mechanical temperature gauge continues to show accurate readings even during power failures — ensuring operators can make decisions quickly.

Accurate and Consistent Readings

Mechanical temperature gauges are a single unit, so have good accuracy under most conditions, and maintain their consistency over a long time. precision, well-calibrated Bourdon tubes.

Cost-Effectiveness

Mechanical temperature gauges are more economical to purchase and maintain. They require no wiring, signal transmitters, or controllers. Once installed, they operate for years without needing spare parts or batteries.

Simple constructions

Many operators also prefer mechanical gauges because they are direct-reading instruments — the pointer movement directly represents the temperature change. There’s no risk of software malfunction, sensor lag, or digital display error, making them more trustworthy in critical safety systems.

Easy Installation

Mechanical temperature gauges are easy to install and require minimal setup. They can be mounted directly on the equipment or remotely using capillary tubes.

FAQ:

Why are xylene filled mechanical temperature gauges so robust?

Xylene filled mechanical temperature gauges use a microbore copper caplliray whose bore is only 0.1mm, the size of a human hair. However its wall thickness is 4X of the bore. In addition, this capillary is protected by a multistrand stainless steel sheathing. So, even if an elephant were to step on it, the capillary bore would not get compressed. We at IIL go so far as to say that the only way to make the capillary fail is to physically cut the sheathed capillary using a hacksaw.