Pressure sensors work unnoticed in some of the most important applications surrounding us, including braking systems in vehicles, engine management, breathing aids in medicine, and manufacturing automation. Though there have been applications of electro-mechanical pressure sensors in earlier models, the preference in newer models is clearly in favour of electronic pressure sensors.

In this article, we’ll cover:

- The evolution of pressure sensors

- Electromechanical and electronic sensors: How do they work in reality?

- How electronic pressure sensors outdo traditional methods of pressure measurement

- Industries where this change is taking place

- What IIL offers to meet market needs

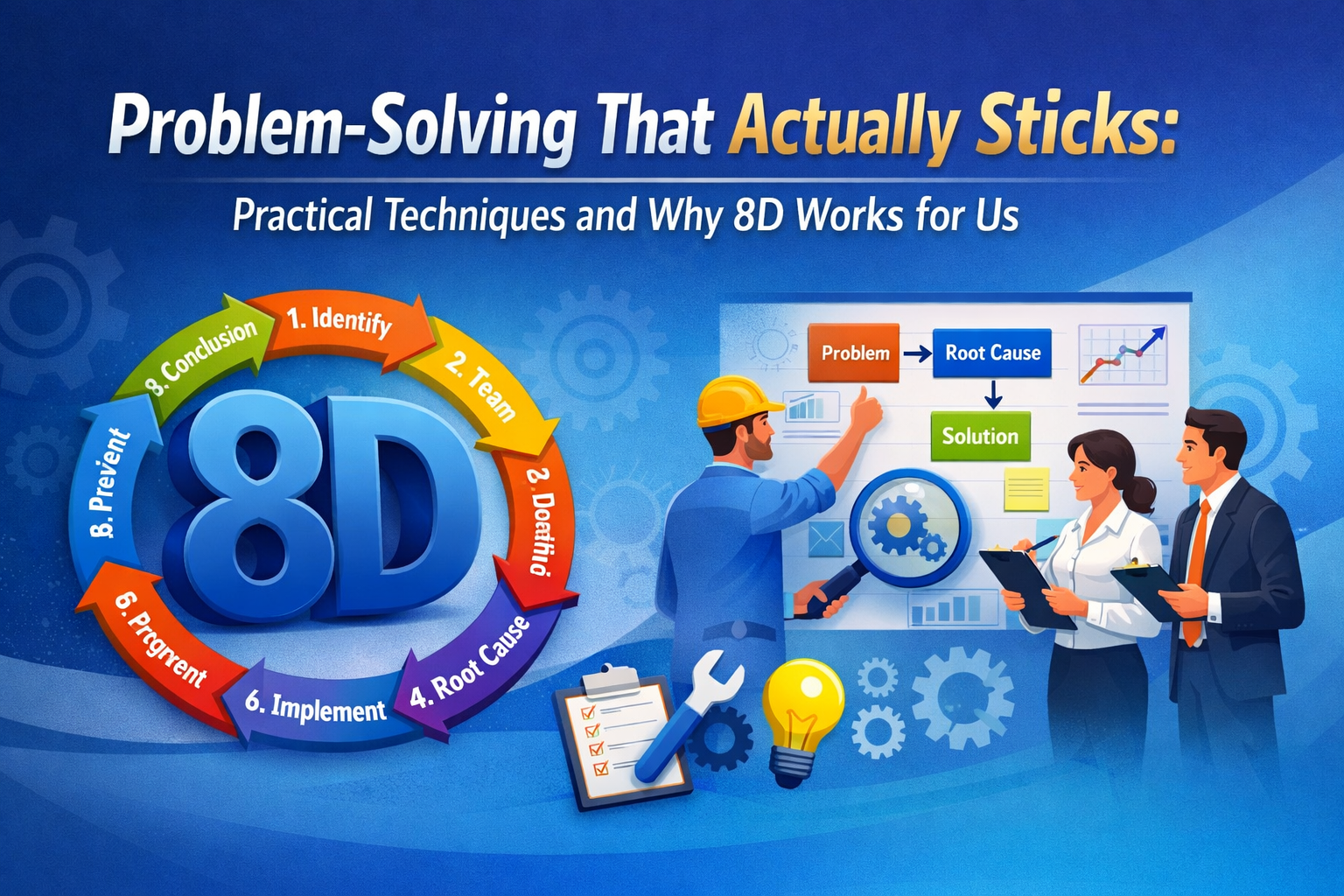

Below we’ll walk through these techniques briefly and then review 8D in details i.e.how we use it day-to-day.

Brief details of problem-solving techniques

- PDCA (Plan–Do–Check–Act) — This is iterative loop. Great for small experiments and continuous improvements.

- DMAIC (Define–Measure–Analyze–Improve–Control) — This is backbone of Six Sigma. Use this when the problem needs statistical analysis and tight controls.

- 5-Whys — Ask why regularly (at least 5 times) until you reach to actual root cause of problem.

- Fishbone (Ishikawa) diagrams — This include all possible causes for problem including Man, Machine,Material, Method and Measurement. Great for team brainstorming and make sure you don’t miss important angles.

- FMEA (Failure Modes & Effects Analysis) — a preventive, Potential risk-based technique to score risks and plan mitigations, typically used during design or process changes.

All of these techniques are useful. When an issue is cross-functional, impact customer, or requires both immediate containment and long-term fixes, the 8D method is often the most practical and reliable choice. This is especially true in complex assemblies such as electronic dashboard instruments and digital instrument panel systems.

What is 8D?

8D stands for Eight Disciplines. It’s a structured, team-based approach designed to solve complex problems and ensure they don’t recur.

- D1 — Define the problem (4W/1H)

- D2 — Form Team

- D3 — Implement Interim Containment Actions

- D4 — Root cause Analysis (5 why)

- D5 — Select and implement Permanent Corrective Actions

- D6 — Implement Preventive Actions

- D7 — Confirm the effectiveness & Horizontal Deployment

- D8 — Congratulate & Close

Two things make 8D powerful: early containment to protect customers and operations, and a disciplined progression from root-cause analysis through verified implementation and systemic prevention.

How we actually use 8D

D1: Define the problem (4W/1H)

A precise problem statement makes the investigation efficient. Replace vague descriptions like “For example, instead of saying ‘display not working,’ specify ‘backlight failure in instrument cluster digital during end-of-line testing” with specific statements: (Quote: “A problem is half solved if defined well.”)

What is actual problem?

Where is problem found?

When Problem Occurred?

Who reported problem?

How much Qty of failed part?

Define all aspects with relevant data evidence.

Note: Never ask ‘Why’ during define the problem.

Evaluate Severity of problem will help in prioritization.

D2: Form Team

8D is a CFT activity. A good 8D team includes all relevant cross function members like Process quality, Production, Supplier Quality, Engineering etc.Assign a clear team leader and capture member roles up front. That role clarity reduces confusion and speeds decisions during the investigation.

Why it matters? diverse perspectives catch blind spots, and having a named leader means actions get tracked and completed.

D3: Implement Interim Containment Actions

Containment buys you time to investigate. Actions include re inspection of stock available at customer site/Transit/ plant, quarantining suspect lots, stopping shipments, adding inspection steps. This is often required when issues occur in customer-critical parts like digital instrument panel or electronic dashboard instruments.

Record containment actions and results so you can later evaluate whether they were sufficient and when they can be withdrawn.

Doing GEMBA audit is also part of containment action.

D4: Root cause Analysis (5 why)

This is section where fishbone diagrams, 5-Whys start. Brainstorm systematically using Fishbone to cover all possible causes. Use 5-Whys to drill into the most likely branches.

In IIL we do root cause analysis for following area

- For occurrence

- For Non Detection

- System root cause

Main aspect of root cause analysis is that we need to validate the cause which determined by analysis i.e. ‘Root cause verification’

Root cause Verification can be done by physical witness of determined event or cause or by simulation of problem by determined cause.

It’s always a typical task to replicate the actual problem in same fashioned since multiple field factors are unknown.

Our prime focus is on root cause verification.

Related Blog : https://indicationinstruments.com/robotic-pointer-fitment-in-instrument-clusters/

D5: Select and implement Permanent Corrective Actions

Generate potential corrective actions for occurrence, non detection & system root cause fixing. Then validate them experimentally. A verified corrective action is demonstrated to fix the problem without introducing new issues. Define acceptance criteria and run controlled trials.

Note: Corrective actions should be in linkage with determined root cause.

D6: Implement Preventive Actions

During analysis we thoroughly study the process, part, design etc and take preventive action for potential risk/problem as a proactive approach.

Note: During implementation of permanent corrective actions/preventive actions. Update work instruction, control plan, FMEA etc. Assign responsibility and timelines for all action points with target date , track them for ontime implementation.

Verify the corrective actions status on regular interval to ensure all are in place.

D7: Confirm the effectiveness & Horizontal Deployment

Its always important to monitor the effectiveness of corrective action in future rejection returns trends/ quality concerns. This evident how much our corrective actions effective.

Deploy the actions horizontally where applicable in same family or similar design products.

D8: Congratulate & Close

Formally close the 8D after a period of monitoring and documented confirmation that targets were achieved.

Capture lessons learnt and celebrate the team.