Pressure sensors work unnoticed in some of the most important applications surrounding us, including braking systems in vehicles, engine management, breathing aids in medicine, and manufacturing automation. Though there have been applications of electro-mechanical pressure sensors in earlier models, the preference in newer models is clearly in favour of electronic pressure sensors.

In this article, we’ll cover:

- The evolution of pressure sensors

- Electromechanical and electronic sensors: How do they work in reality?

- How electronic pressure sensors outdo traditional methods of pressure measurement

- Industries where this change is taking place

- What IIL offers to meet market needs

Evolution of Pressure Sensors

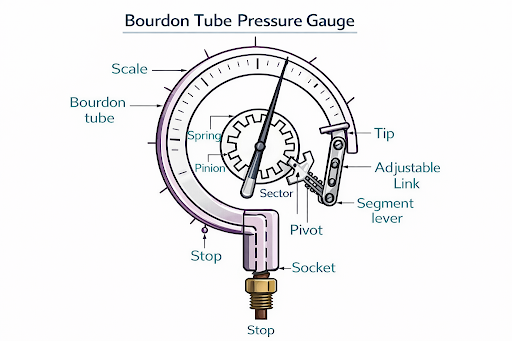

1. Mechanical Pressure Measurement (The Starting Point)

Early pressure measurement relied entirely on mechanical movement:

- Bourdon tubes

- Bellows

- Spring-loaded diaphragms

When force was applied to these elements, they distorted. These actions caused a needle to sweep across a dial. Such devices were simple, robust, and did not consume any power; they couldn’t transmit any electrical signal, remote monitoring, or data acquisition either.

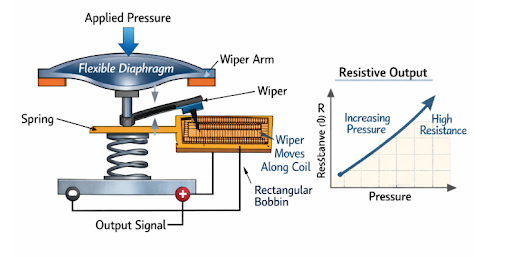

Electromechanical Pressure Sensors (The Transition Phase)

Electromechanical sensors were an intermediary stage between mechanical and electronic designs.

- Pressure pushes a mechanical diaphragm

- A diaphgram will physically bent

- This triggers a switch, potentiometer, or strain gauge

- The mechanical process is translated into a fundamental electric signal

Key limitation: There is a friction due to mechanical motion.

3. Electronic Pressure Sensors (Modern Standard)

Electronic pressure sensors made it possible to eliminate any kind of dependence on mechanical elements to a large extent. Based on MEMS technology and semiconductor technology, they:

Electronic vs. Electromechanical Pressure Sensors

Accuracy & Precision

Electronic sensors provide the following functions:

- High resolution

- Excellent repeatability

- Integrated temperature correction

In an electromechanical sensor, there is a mechanical movement that causes drift with respect to time

Reliability & Lifetime

Electromechanical sensors:

- Wear out mechanically

- Require frequent recalibration

Electronic sensors:

- Free from mechanical fatigue

- Long lasting performance

Response Time

These sensors respond almost instantly and are useful for:

- Automotive braking

- Industrial control loops

- Medical life-support systems

Mechanical inertia slows electromechanical sensors.

Size & Integration

Thanks to MEMS:

- Electronic sensors are compact

- Easy to mount on PCBs

- Ideal for IoT and embedded systems

Electromechanical circuits are larger and more difficult to miniaturize.

Connectivity & Intelligence

Electronic pressure sensors facilitate:

- I²C, SPI, CAN, analog outputs

- Diagnostics and fault detection

- IoT compatibility

Electromechanical sensors do not have smart characteristics.

Total Cost of Ownership

Although electronic sensors would cost a bit more initially:

- They last longer

- Require less maintenance

- Shorten downtime

Over time, they’re more economical.

Applications Propelling the Markets

- Automotive: TPMS, engine controls, braking systems

- Medical: Ventilators, patient monitoring, infusion pumps

- Industrial: Hydraulics, pneumatics, process automation

- Consumer electronics: HVAC, wearables

- Aerospace: Altitude and cabin pressure monitoring

What IIL offers to meet market needs:

Electromechanical Pressure sensor:

- It has pressure range up to 28 bar

- With resistive output voltage

- Available in different thread size for fitment

- It is passive sensor so does not require power.

Electromechanical Pressure sensor

- Is has pressure range up to 28 bar

- Available in gauge and absolute pressure

- Operating voltage: 5V (regulated), 5 to 32V for 12/24V vehicle

- Output Voltage available in 0.5 to 4.5V and 0.5 to 4.9V

- Different thread sizes are available for fitment.

- Temperature compensated

- Housing available in brass/ steel or free cutting steel material

Conclusion

The shift from electromechanical to electronic pressure sensors is no longer a trend but an evolutionary process. The need for accuracy, speed, miniaturization, and digital intelligence in modern systems is effortlessly satisfied by electronic pressure sensors.

Frequently Asked Questions

Q1. What’s the biggest difference between electronic and electromechanical sensors?

Electronic sensors can translate pressure directly into an electrical signal, whereas electromechanical sensors must first use a mechanical motion.

Q2. Are electronic pressure sensors more accurate?

Yes — they provide increased accuracy, improved stability, and reduced drift.

Q3. Are electronic sensors calibrated?

Most of them are calibrated in the factory, although safety-critical applications may demand periodic recalibration.

Q4. Can electronic sensors withstand severe environments?

Absolutely. Absolutely. They have required specifications for withstanding high temperature, vibration, dust, and humidity.

Q5. Are electromechanical sensors in current usage?

Sometimes — in simplified or legacy systems, in cases when accuracy is not necessary.